Drip Off System , Drip Off With Intradeck On Heidelberg Sormz, Drip Off Technology,Offset printing machine.

Product Details:

- Type Uv dripoff coating machine

- Material UV/IR

- Capacity 300W PER INCH Pcs/min

- Printing Speed High speed

- Computerized Yes

- Automatic Grade Automatic

- Plate Type Screen Printer

- Click to View more

Drip Off System , Drip Off With Intradeck On Heidelberg Sormz, Drip Off Technology,Offset printing machine. Price And Quantity

- 1500000 INR/Number

- 1 UNIT Number

- 500000.00 - 2500000.00 INR/Number

Drip Off System , Drip Off With Intradeck On Heidelberg Sormz, Drip Off Technology,Offset printing machine. Product Specifications

- High speed

- 300W PER INCH Pcs/min

- 300W-400W INCH

- 30 Watt (w)

- Uv dripoff coating machine

- Uni-Directional

- Screen Printer

- Yes

- 26

- 100%

- Automatic

- 20 Inch (in)

- UV/IR

- Density Adjustment

- UV Curing Ink

- Frequency Speed Control

Drip Off System , Drip Off With Intradeck On Heidelberg Sormz, Drip Off Technology,Offset printing machine. Trade Information

- NEW DELHI

- Contact us for information regarding our sample policy

- All India

Product Description

What is Drip-off coating?

Hybrid Coating/Drip Off coating is highly required because with this technology we can control Matt and Gloss effects as per our own preference. It has a special feature that we can control the effect according to graphic or geometry, it gives us independence to think creatively .It is a quick technique to produce attractive images. Drip off printing can be done on small to large surfaces. Often, it is also combined with UV printing technique

As we expose design on offset Printing Plate/CTP plate that would be coating achieve on the substrate according to our own choice

Why Drip-off coating require:

Drip-off coating exceedingly demand in a industrial printing level that is why it can make a protective layer on substrate increase their long lasting period and attractive effect of gloss & matt by expose us. There is its several advantage as i explain below:

High Coating Quality Finishing

Durability

Fast Curing

Environmental Friendly

Versability

Attractivness

Both Achieve Matt & Gloss

Multi Colour & Substrate

High Speed

Geometerical or Graphically control

Solution we Provide:

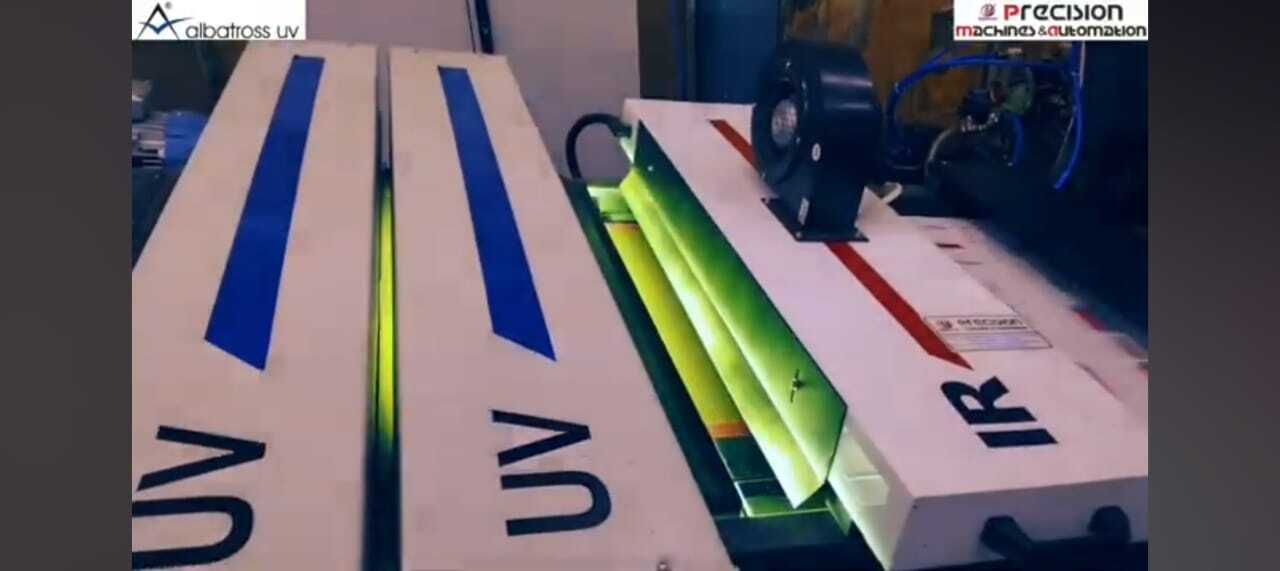

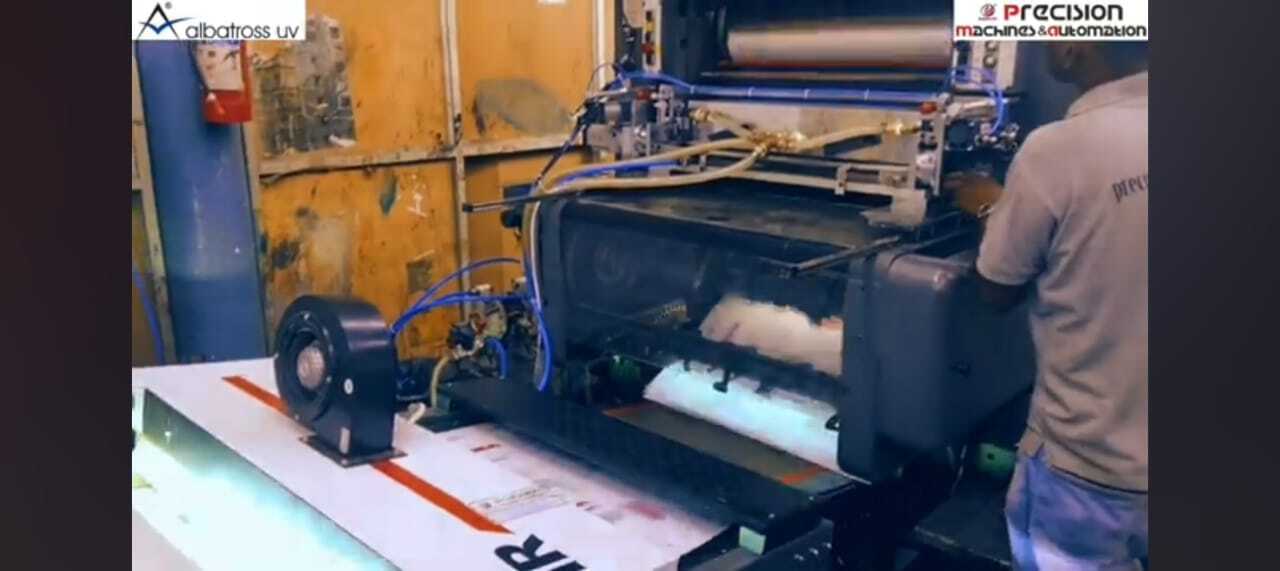

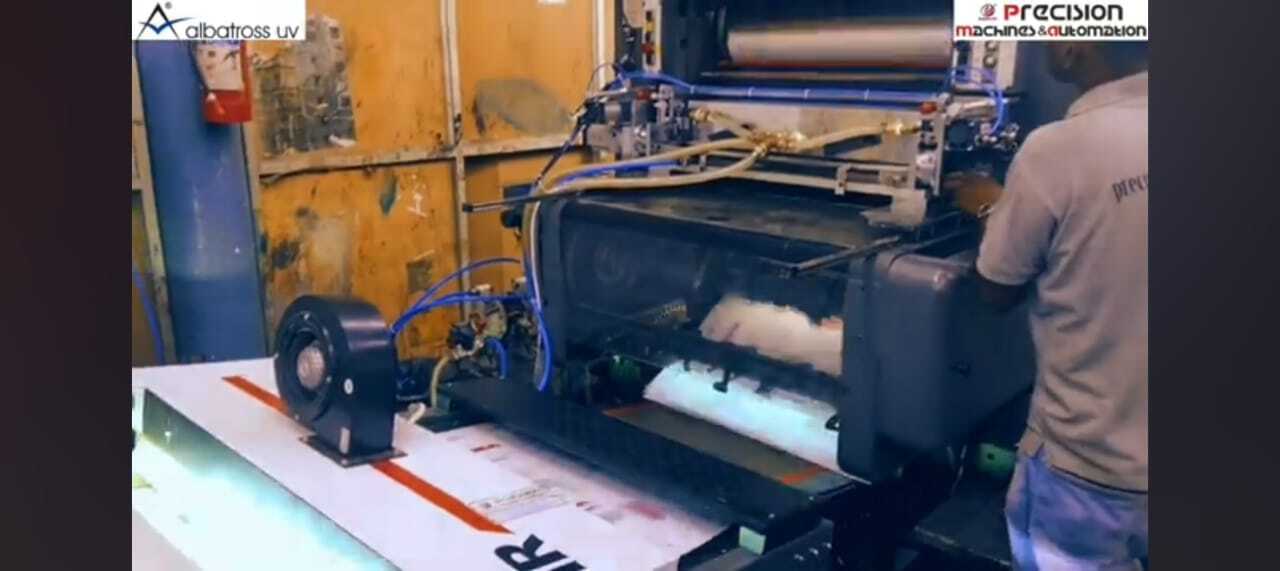

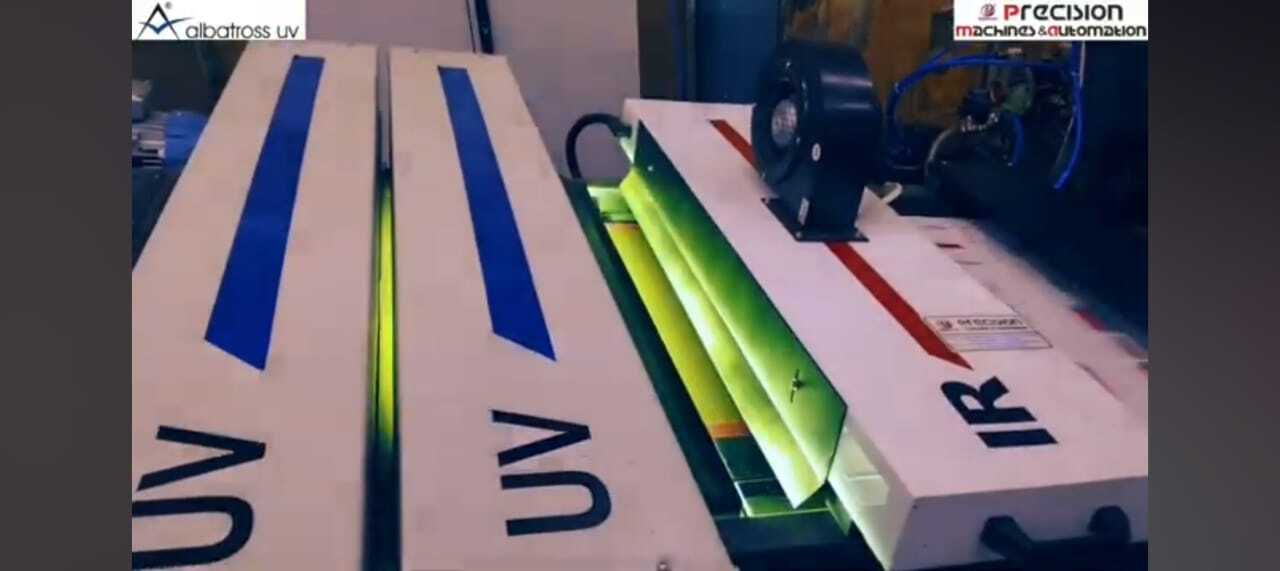

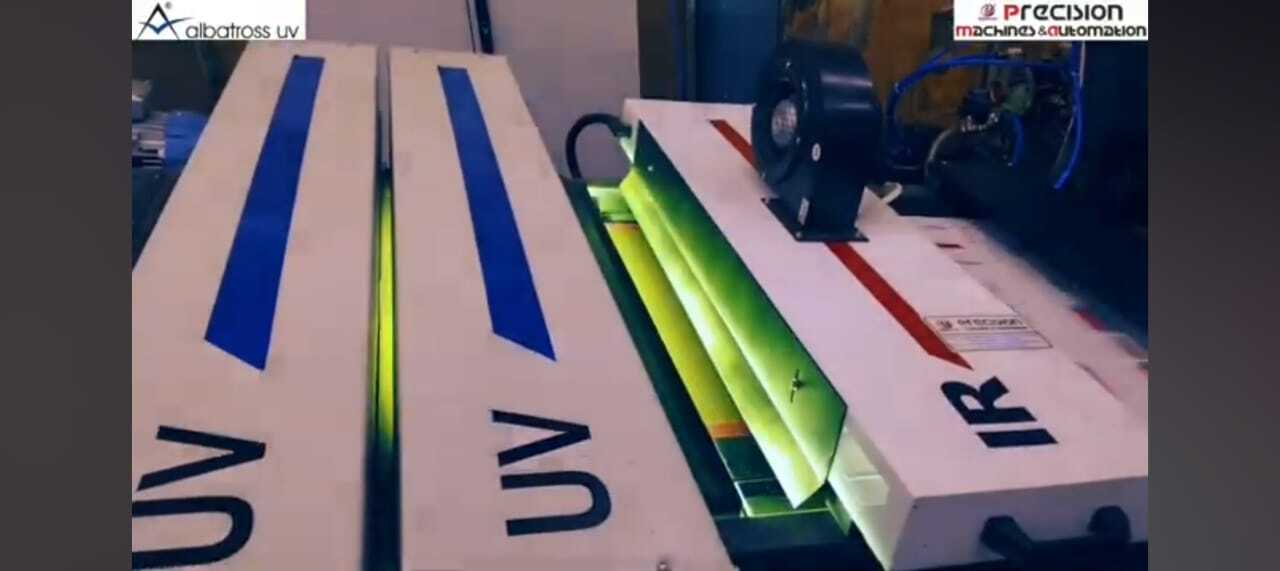

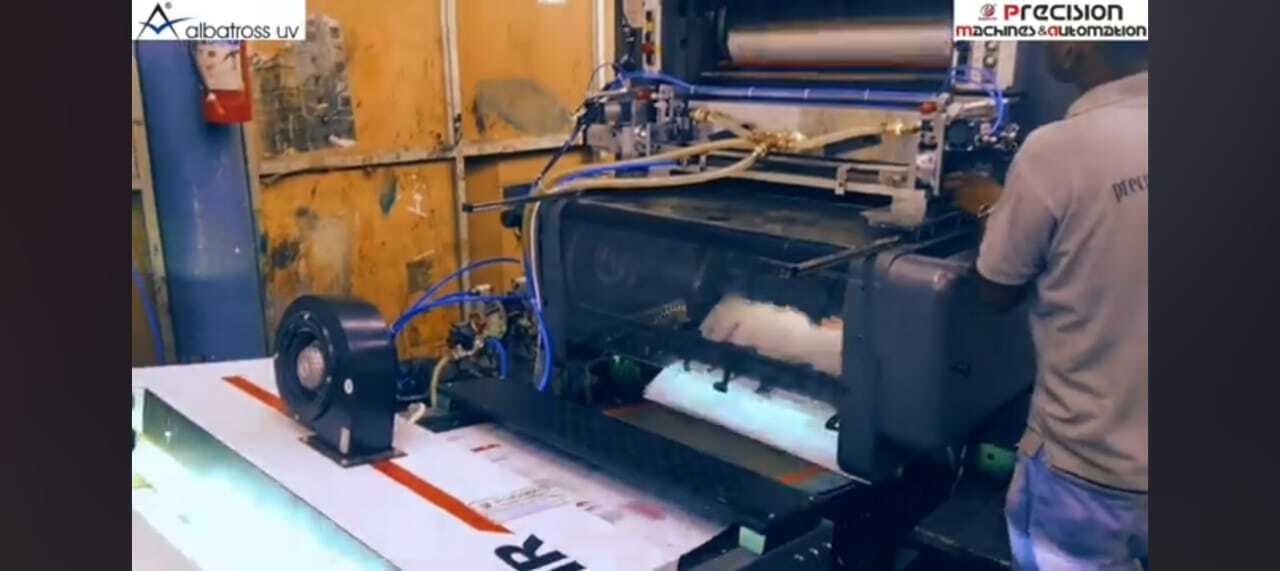

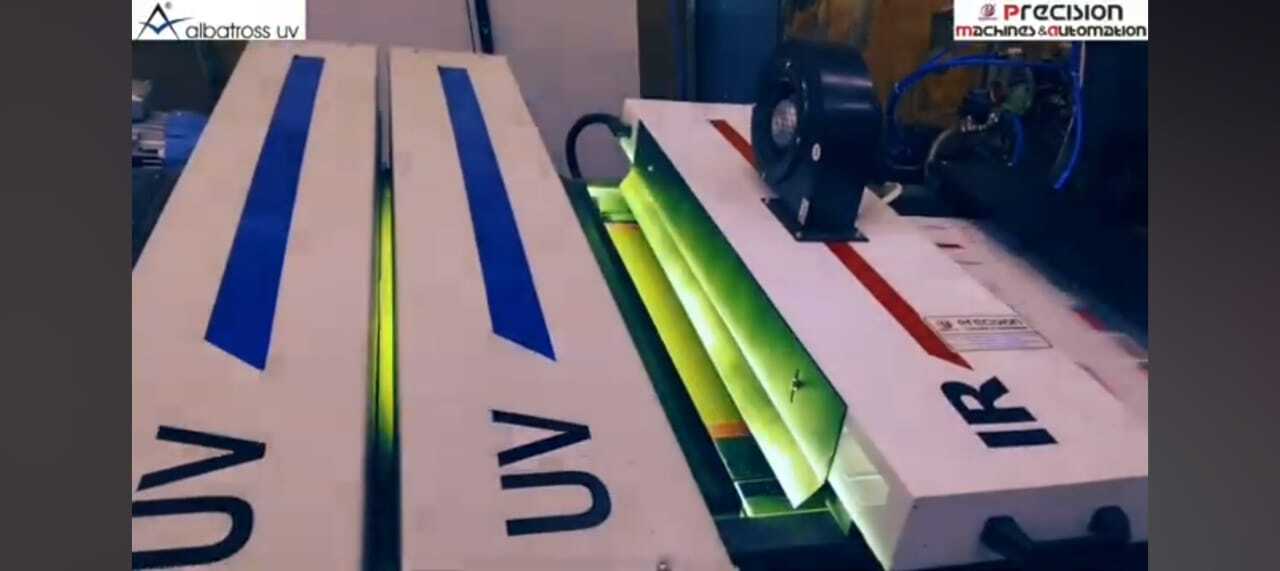

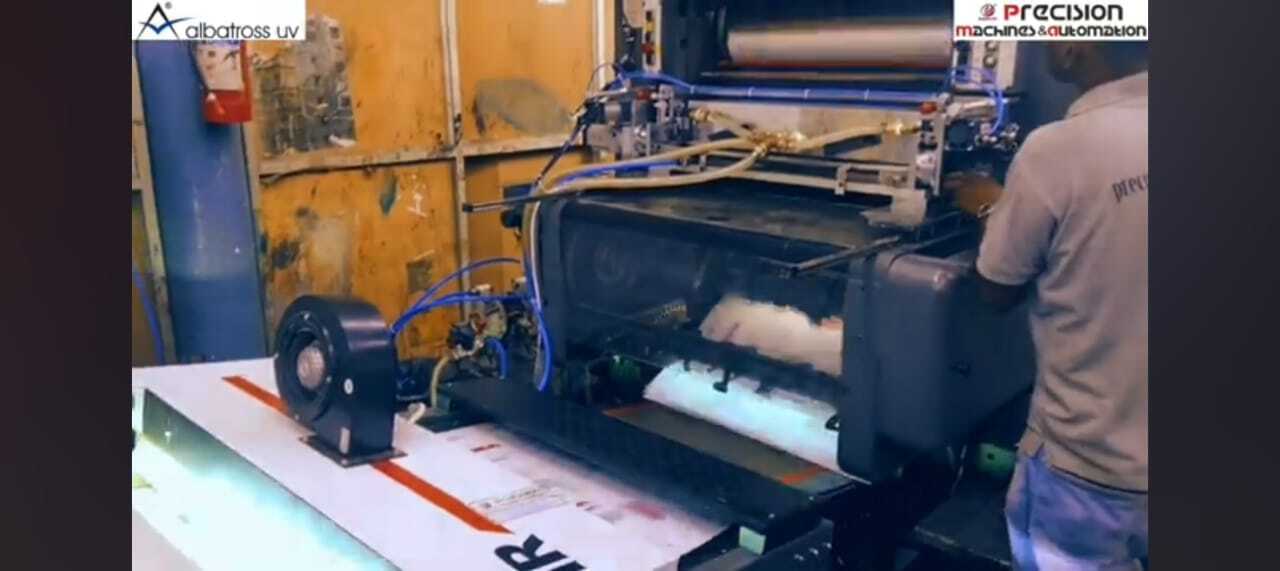

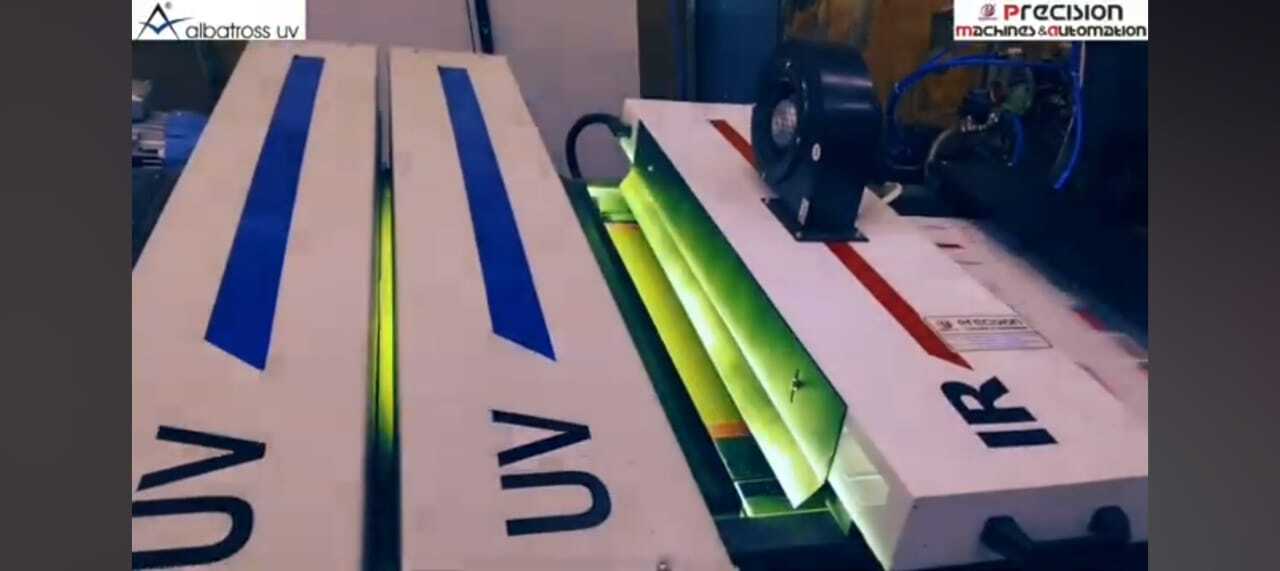

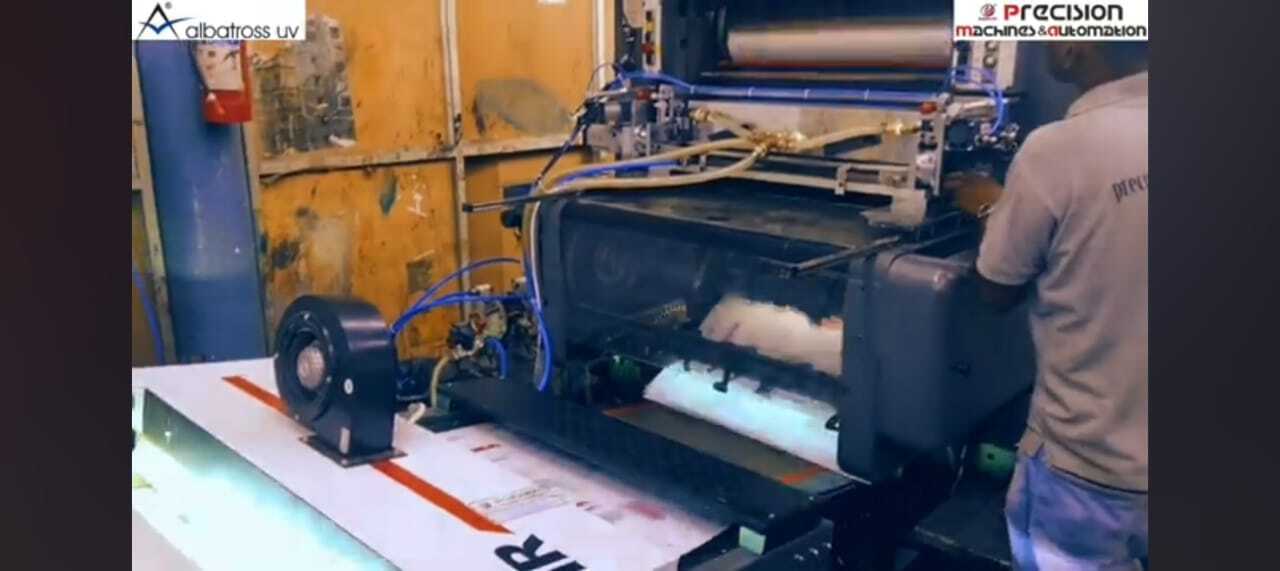

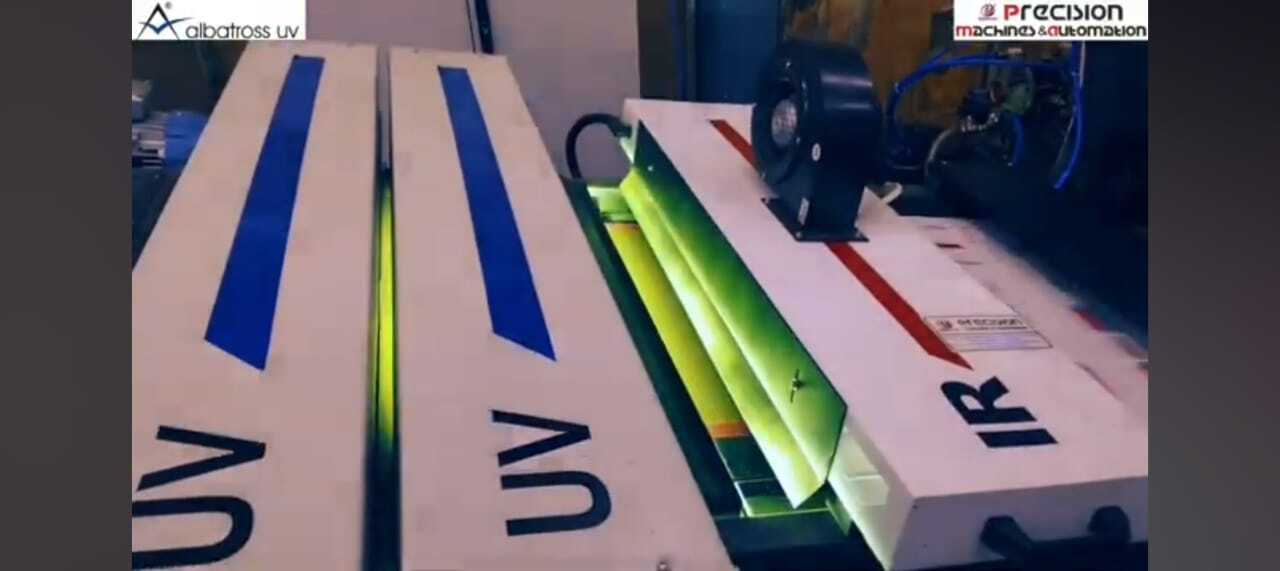

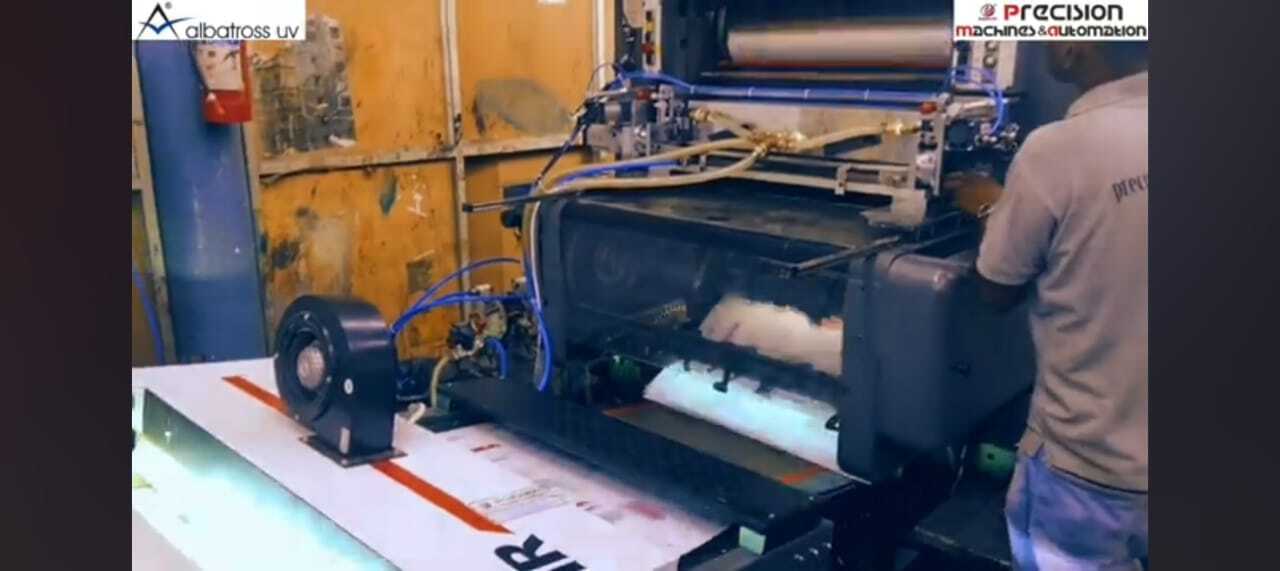

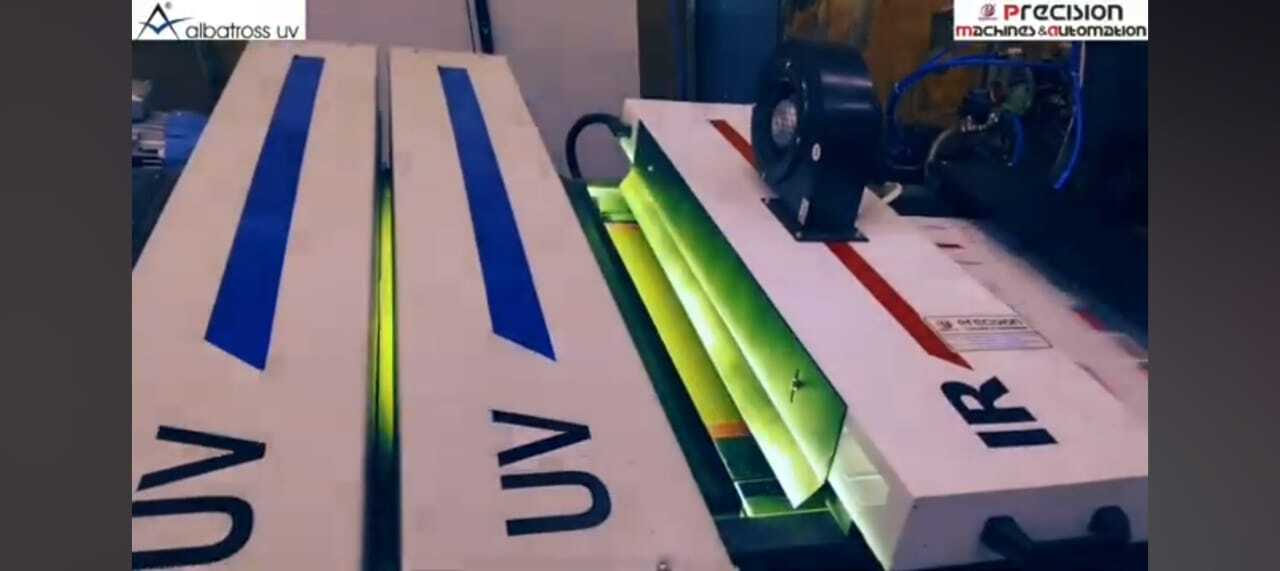

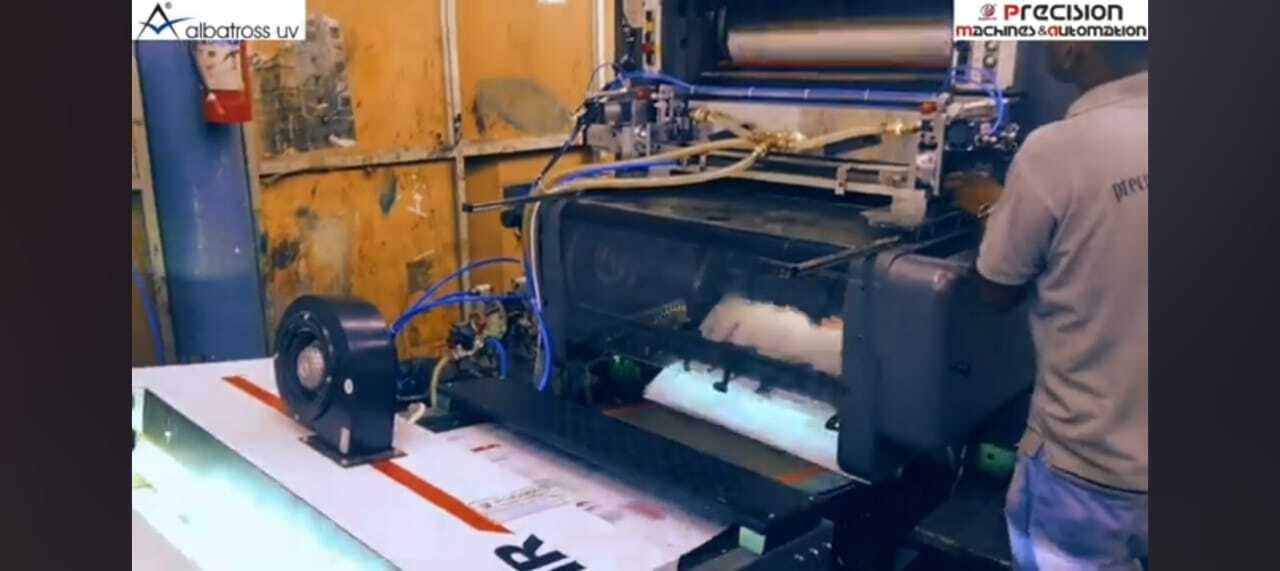

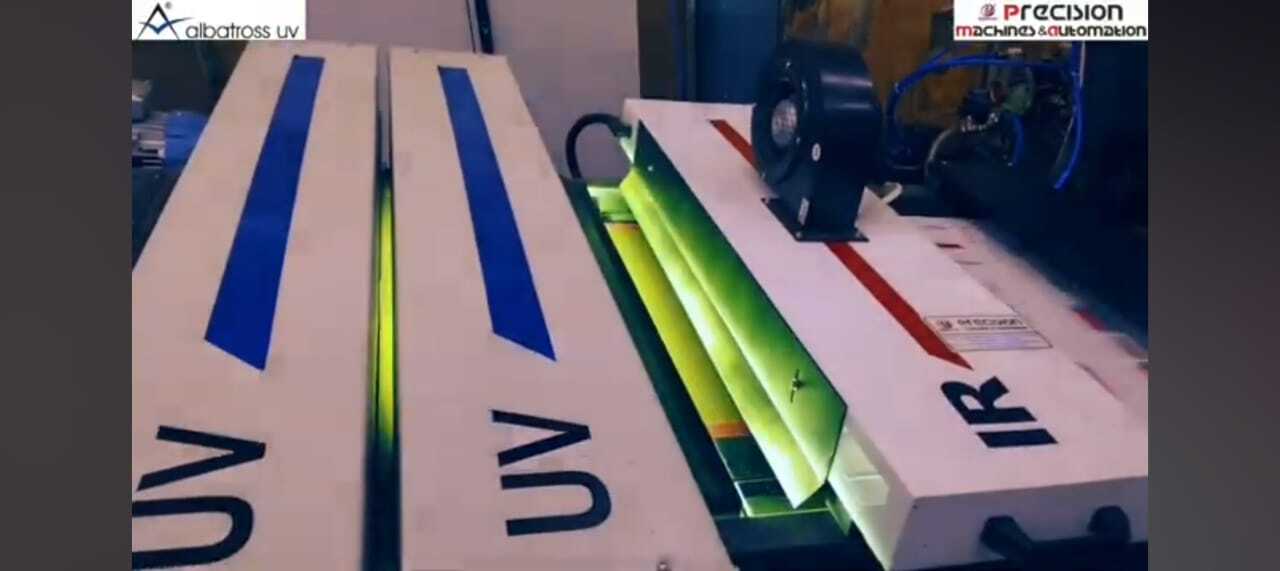

Uv drip off system for uv drip off effect and other coatings. Coater is provide with chamber which is engaged in continuous doctoring as it is having, 2 nos doctoring blade. Aro diaphragm pump is used to continuously pump uv varnish into the chamber.Uv system is having its own touch screen. It can control all 3 modules at the same time uv intradeck between printing color 1 and 2, uv coating attachment and uv conveyor with uv lamp.

UV COATING ATTACHMENT:

At the 1ststation make matt effect that area we expose on the printing Plate in this process used Inkduct roller-on the plate cylinder have Printing plate-blanket cylinder-substrate. Getting matt effect help with that rollers on the sheet

UV INTERDECK IN MID:

After 1stmatt effect used uv interdeck for curing matt on sheet 75% to 80% it comes between 1St& 2ndstation of offset printing machine

2ndSTATION UV COATING ATTACHMENTWITH ANNILOX ROLLER Or CHAMBER:

At the 2ststation make glossy effect on the full sheet we disexpose that area on the printing Plate make gloss or shiny look by Annilox roller or chamber in this process work same as first station but for shiny effect

CONVEYOR WITH UV LAMP:

When sheet gets both effect matt or Gloss it have liquidness. Conveyor with uv lamp used for fully curing or highly shine of offset printing

Other Products in 'UV LED Curing Technology' category

|

PRECISION MACHINES & AUTOMATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |